Aircraft Aluminum Extrusions - TW Metals has over 20 locations strategically located in North America, Europe and Asia supporting the world's aerospace industry. Aluminum extrusions are stocked by Army Navy Design (AND) and airframe manufacturers part numbers including Boeing, Airbus, Lockheed-Martin, Embraer, Bombardier and many others.

New Source Corporation offers this service to all our defense and commercial sector clients. Our ultimate goal is to help you quickly, efficiently, and affordably create an aluminum extrusion that performs the necessary functions using our extensive aerospace metal experience.

Aircraft Aluminum Extrusions

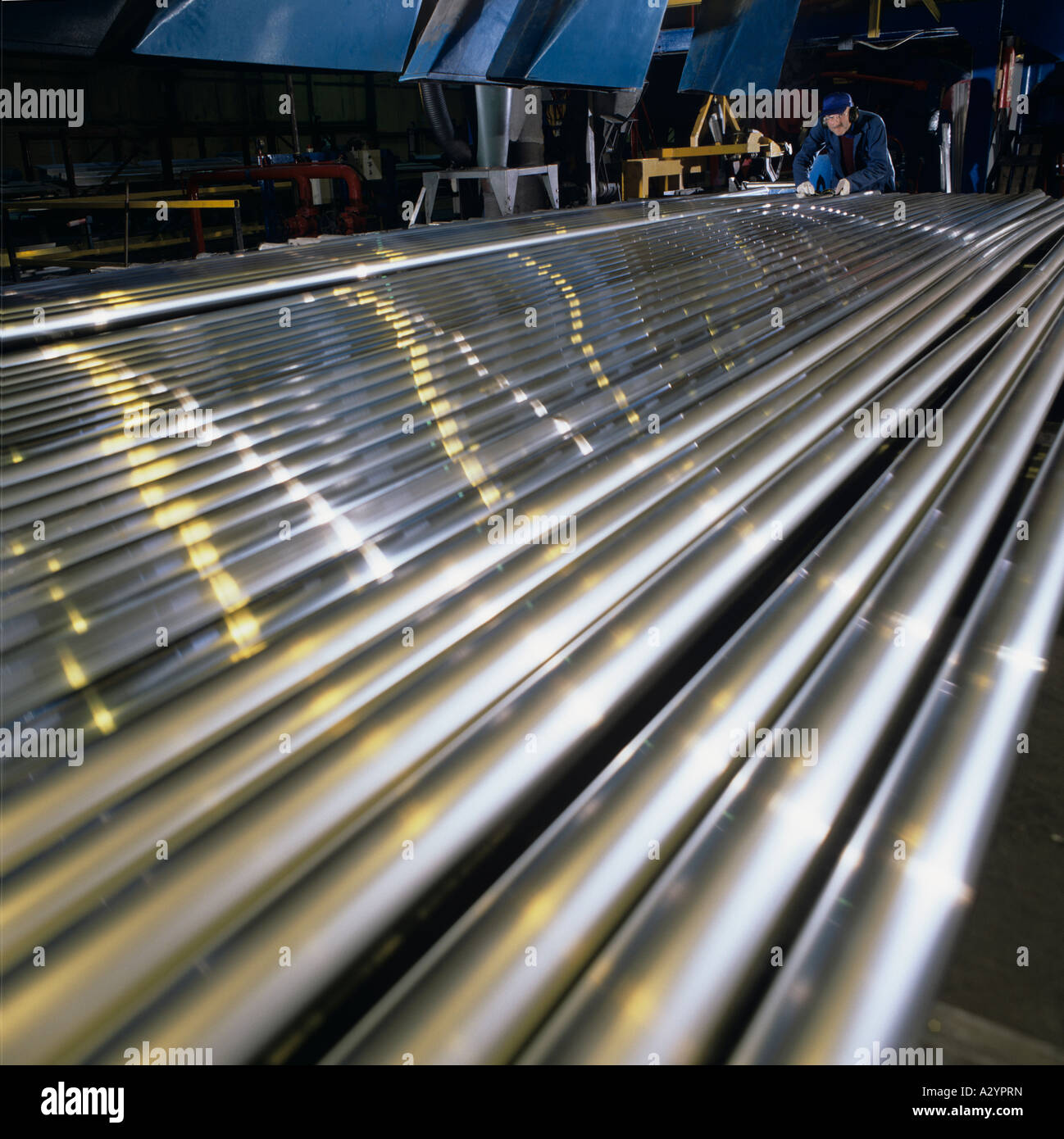

At Aircraft Extrusion Company we pride ourselves with the ability to provide not only an extensive range of aerospace aluminum shapes in 2024 and 7075, but as a vertically integrated company our capabilities expand beyond material distribution but also include custom shapes, fabricated extruded shapes and cnc prototype

Who We Are

machining specializing in track design and supply. As a one-stop shop, we offer a vast array of aluminum grades and have an extensive selection of hard alloy extruded shapes in stock. We have add-on capabilities to meet the demand for specialty pieces and precise cutting services.

With our CNC in-house capabilities Aircraft Extrusion Company is designing and manufacturing custom seat track for a wide range of aircraft including Cessna, Piper, experimental and prototype aircraft. With same-day quoting and fabrication done in days not weeks, our service is unparalleled.

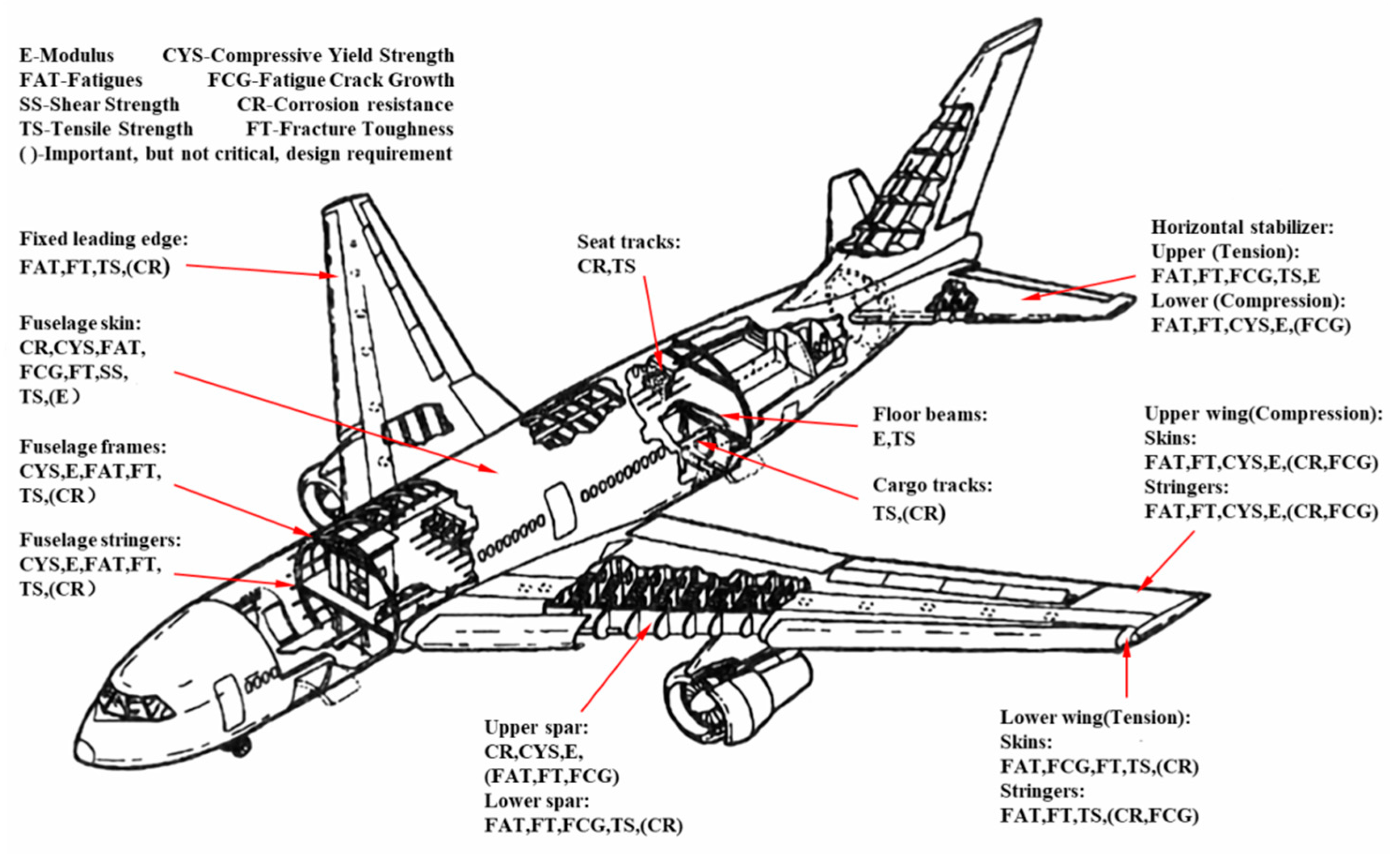

We offer a wide host of engineering services including CAD design and 3D modeling. We take your design from napkin to a reality The extrusion process allows manufacturers to control and concentrate the strength of aluminum to where it is needed most.

Internal reinforcement and varying wall thicknesses can be modified to meet the specified needs of the aluminum extrusion profile design. Zinc is the major alloying element in this group, and when coupled with a smaller percentage of magnesium results in heat-treatable alloys of very high strength.

Custom Seat Tracks

Other elements such as copper and chromium are also added in small quantities. The most common member of this group is 7075, which is among the highest strength alloys available and is used in airframe structures and for highly stressed parts.

We stock 7050, 7075, 7150 & 7178 grade extrusions. Since 1992, our company has been a major distributor of aerospace-grade aluminum extrusions. We are a trusted provider of all the products and services you need to get the job done.

Large orders and next-day shipments are not a problem for our experienced team. An aluminum extrusion offers excellent abrasion and corrosion resistance. Aluminum does not rust and is further protected by the naturally occurring oxide coating found on the material.

Finishing processes, such as anodizing, further enhance aluminum's natural corrosion resistance. Weight reduction is a growing concern in areas such as transportation, and using lighter parts makes shipping less costly. Aluminum is an attractive material for applications involving moving parts since it is easier to handle and weighs considerably less than other commonly used materials.

Xxx Series

Alloys in this group contain silicon and magnesium in approximate proportions to form magnesium silicide, thus making them heat-treatable. The major alloy in this series is 6061, one of the most versatile in the heat treatable alloys.

Though less strong than most of the 2xxx or 7xxx alloys, the magnesium-silicide alloys possess good formability and corrosion resistance, with medium strength. We stock 6061 & 6063 grade extrusions. The unique flexible properties of aluminum allow the raw material to be easily machined and cast.

With one-third the density and stiffness of steel, aluminum can form strong and stable products, particularly when alloyed with other complementing metals. With the help of our manufacturing partners, New Source Corporation offers complete custom design solutions.

Our creative team understands that even though we carry the largest raw materials and aerospace metals on the market, manufacturers do not always produce the required parts to desired specifications. Our sales team are available and quoting is immediate.

Corrosion Resistant

Stock orders can be shipped on an A.O G basis with our custom built packaging to ensure your material arrives on time and in damage free. New Source Corporation offers vendor-managed inventory and is a key supplier for various government prime contractors.

We also service the MRO market, specializing in managing AOG situations. Our extensive experience in the industry allows us to handle all your aluminum extrusion needs with ease. Aluminum is approximately 1/3 the weight of brass, copper, steel, and iron and is 2 ½ times less dense than steel.

Despite aluminum's strength, it is incredibly lightweight, making aluminum extrusions the perfect solution for various industries and applications. Copper is the principle alloying element in this group. These alloys require solution heat treatment to obtain optimum properties.

It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to its high strength and fatigue resistance, 2024 is widely used in aircraft structures, especially wing and fuselage structures under tension.

Xxx Series

We stock 2014, 2024 & 2219 grade extrusions.

aerospace aluminum extrusions, aircraft extrusions catalog, stock aluminum extrusions, aerospace extrusion catalog, aircraft extrusion company, tierney extrusions cross reference, aircraft extrusion co, aerospace extrusion suppliers