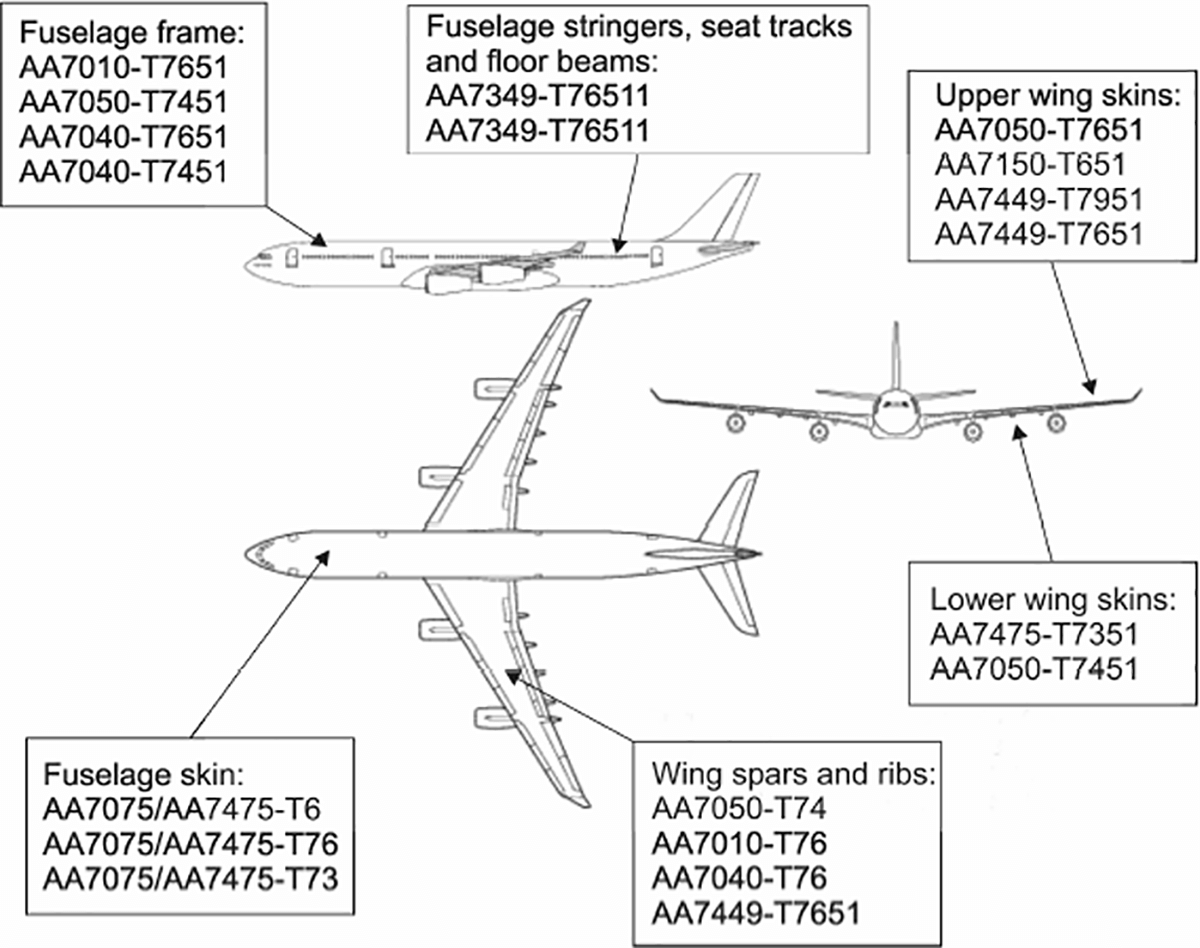

Aircraft Aluminum Plate - 2024, 7075, 7475, 7150 and 7055 aluminum alloy are typical aircraft aluminum plates, featuring low density, high specific strength, good corrosion resistance and excellent formability, which is used for fuselage skins, wing and stabilizer skins, fuselage bulkheads, fuel tanks,

connectors and other structures. -YK Aluminum is a global leading manufacturer with 15 years production experience, specialized in manufacturing of aluminum sheet, aluminum plate, aluminum coil, aluminum foil, aluminum strip, and etc.35000m2 factory area250,000 tons annual output120+ expanded countries10000 + finished projects

Aircraft Aluminum Plate

Aluminum plays a vital role in the construction of aircraft. Its high resistance to corrosion and good weight to strength to cost ratio makes it the perfect material for aircraft construction. But the one property that makes aluminum the ideal metal for aircraft construction is its resistance to UV damage.

Why Choose Aircraft Aluminum Plate

Plate size is not the same as boot/shoe size. Your boot/shoe size will tell us the plate size you need. Providing us with the length of your sole (measured to the nearest centimeter) will also help us determine the proper plate size.

YK ALUMINUM develops, produces and sells aviation aluminum to all over the world. With 15 years of production experience, YK ALUMINUM always provides high value-added aluminum products to meet the challenging demands of its clients and step into new markets.

The Reactor Pro series features a stronger grade of extruded aircraft aluminum and an improved design for the toe stop housing. Additionally, this plate will come standard with 10-degree kingpins and cold-forged, black anodized solid aluminum trucks with fine threaded adjustable pivot arms.

Precise adjustment of these pivot arms allows for maximum response on the track. The aircraft aluminum plate is finished with a brilliant high-polish steel blue color and laser etched graphics - when all is said and done the Reactor Pro represents the pinnacle of plate design, beauty, and performance!

– H

This alloy is best known for its high corrosion resistance and finish. It is easy to weld and has almost the same strength as mild steel. Grade 6061-T6 is often used to make landing mats for aircraft, truck bodies, and frames as well as structural components.

It can be fabricated using the most common techniques which is an excellent property. Haomei Aluminum always follows the highest international standards in an industry where nothing less than the best is tolerated. We specialize in providing a wide range of aircraft aluminum plates for different parts of airplanes such as fuselage skin, wing panels, tail wing, stringers, ribs, structural parts, etc.

The Reactor Pro series features a stronger grade of extruded aircraft aluminum and an improved design for the toe stop housing. Additionally, this plate will come standard with 10-degree kingpins and cold-forged, black anodized solid aluminum trucks with fine threaded adjustable pivot arms.

Precise adjustment of these pivot arms allows for maximum response on the track. The aircraft aluminum plate is finished with a brilliant high-polish steel blue color and laser etched graphics - when all is said and done the Reactor Pro represents the pinnacle of plate design, beauty, and performance!

What Is Aluminum Plate

6061 Aluminum Sheet has high corrosion resistance and finish. is easy to weld and has almost the same strength as mild steel. Mats in aircraft, truck bodies, and frames as well as structural components often use grade 6061-T6.

It can be fabricated using the most common techniques which is an excellent property. RollerSkateNation.com © All rights reserved. | Sitemap | design by efelle | Customer ID: • Items sold in new condition must be returned in new condition and with their original product box in order to receive a full refund.

Items sold as new that are returned used (showing scuffs, dirt or other signs of use) or missing components are subject to a 10%-20% damage fee (deducted from refund). Grade 2024-T3 is the most common high-strength aluminum alloy.

It is often considered aircraft quality. It has excellent fatigue resistance even though its corrosion resistance is lower than that of 6061. This aluminum alloy sheet is commonly used to make the fuselage, wing skins, aircraft structure, and cowls of most airplanes.

It's also ideal for repairs and restoration because it has a shiny finish. HOLIDAY EXTENSION: For orders placed between November 1st, 2022 and January 1st, 2023 we will accept returns up to 60 days after the date your order was delivered.

Our standard exchange policy (90 days) remains in effect. • Items sold in new condition must be returned in new condition and with their original product box in order to receive a full refund. Items sold as new that are returned used (showing scuffs, dirt or other signs of use) or missing components are subject to a 10%-20% damage fee (deducted from refund).

The primary role of this aluminum alloy is to strengthen aluminum aircraft structures. The alloy is made from a careful mixture of copper, magnesium, and zinc to give it extra strength. However, because of copper, it is difficult but not impossible to weld.

Once anodized, it has a beautiful finish and has the best machinability. 2024 Aluminum Sheet is the most common high-strength aluminum alloy. It belongs to aircraft quality. It has excellent fatigue resistance even though its corrosion resistance is lower than that of 6061. The fuselage, wing skins, aircraft structure, and cowls of most airplanes use aluminum alloy sheets.

It's also ideal for repairs and restoration because it has a shiny finish. Through the application of aluminum alloy, the aircraft weight can be reduced by 10%, thereby improving fuel efficiency. Due to the aircraft aluminum's good fatigue resistance and damage tolerance, the inspection period can be extended and the maintenance cost of the spacecraft can be reduced.

5052-H32 is a non-heat treatable aluminum alloy and has one of the highest strengths in its class. It is not structural but has high fatigue strength compared to other alloys. It also possesses excellent corrosion resistance, particularly in marine applications.

Its excellent workability makes this aluminum sheet ideal for the construction of fuel tanks. The primary role of the 7075 aluminum plate is to strengthen aluminum aircraft structures. a careful mixture of copper, magnesium, and zinc made this alloy, giving it extra strength.

However, because of copper, it is difficult but not impossible to weld. Once anodized, it has a beautiful finish and has the best machinability. In addition to aircraft aluminum applications, spacecraft also use aluminum. Its unique properties are of even more value in this application.

Up to 90% of aluminum components are made in spacecraft. Space stations like the Skylab also use the material and are expected to make even more appearances in manned space exploration. In addition to aircraft applications, aluminum is also used in spacecraft.

Its unique properties are of even more value in this application. Most spacecraft are made of up to 90% aluminum components. The material is also used in making space stations like the Skylab and is expected to make even more appearances in manned space exploration.

Plate size is not the same as boot/shoe size. Your boot/shoe size will tell us the plate size you need. Providing us with the length of your sole (measured to the nearest centimeter) will also help us determine the proper plate size.

HOLIDAY EXTENSION: For orders placed between November 1st, 2022 and January 1st, 2023 we will accept returns up to 60 days after the date your order was delivered. Our standard exchange policy (90 days) remains in effect.

This aluminum sheet has great workability and is one of the most widely used aluminum alloys. It is made from a blend of pure aluminum and manganese. This sheet is also non-heat treatable but can be deep drawn, welded, spun, or brazed.

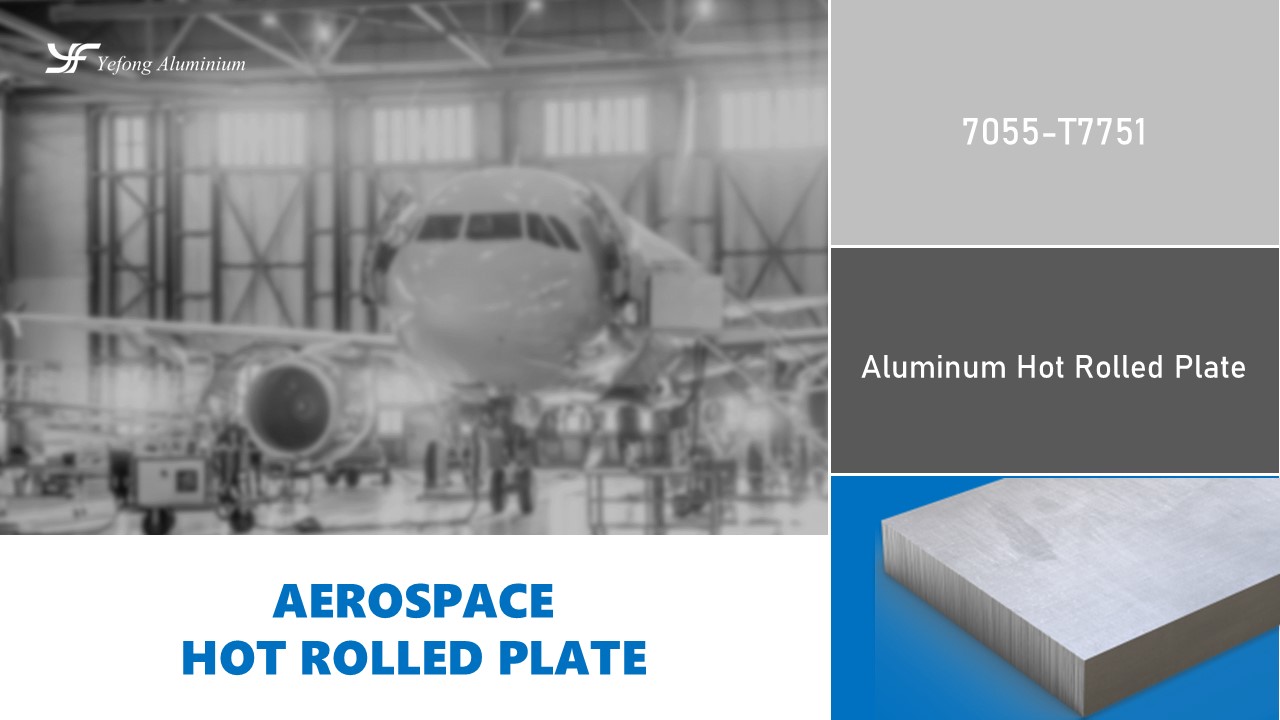

It's perfect for making cowls in aircraft and baffle plating. 7150-T77 aluminum plate is a heat treatable wrought alloy, which meets the requirements of corrosion performance without sacrificing the strength of the alloy. It is used in the aerospace industry for manufacturing aircraft components.

Heat treatment can improve its anti-corrosion properties with a corresponding decrease in strength. As a global leading aviation aluminum supplier, YK ALUMINUM has a 35000m2 factory area with 4 large production lines and 6 processing centers, and has continuously invested in acquiring new technologies and upgrading existing facilities to the latest technological standards.

aircraft aluminum sheet, aircraft quality aluminum, aircraft aluminum pipe, aircraft aluminum sheets for sale, aircraft aluminum alloy, aircraft aluminum sheet metal, aircraft aluminum suppliers, cheap aluminum plate