Aircraft Accelerometer - When something goes wrong in an aircraft, for whatever reason, it's critical that investigators have enough information to reconstruct the conditions and factors that lead up to the problem. With a hermetically sealed housing, your single-, dual- or tri-axial sensors will be ready to tell their stories – even in the toughest, harshest operational environments.

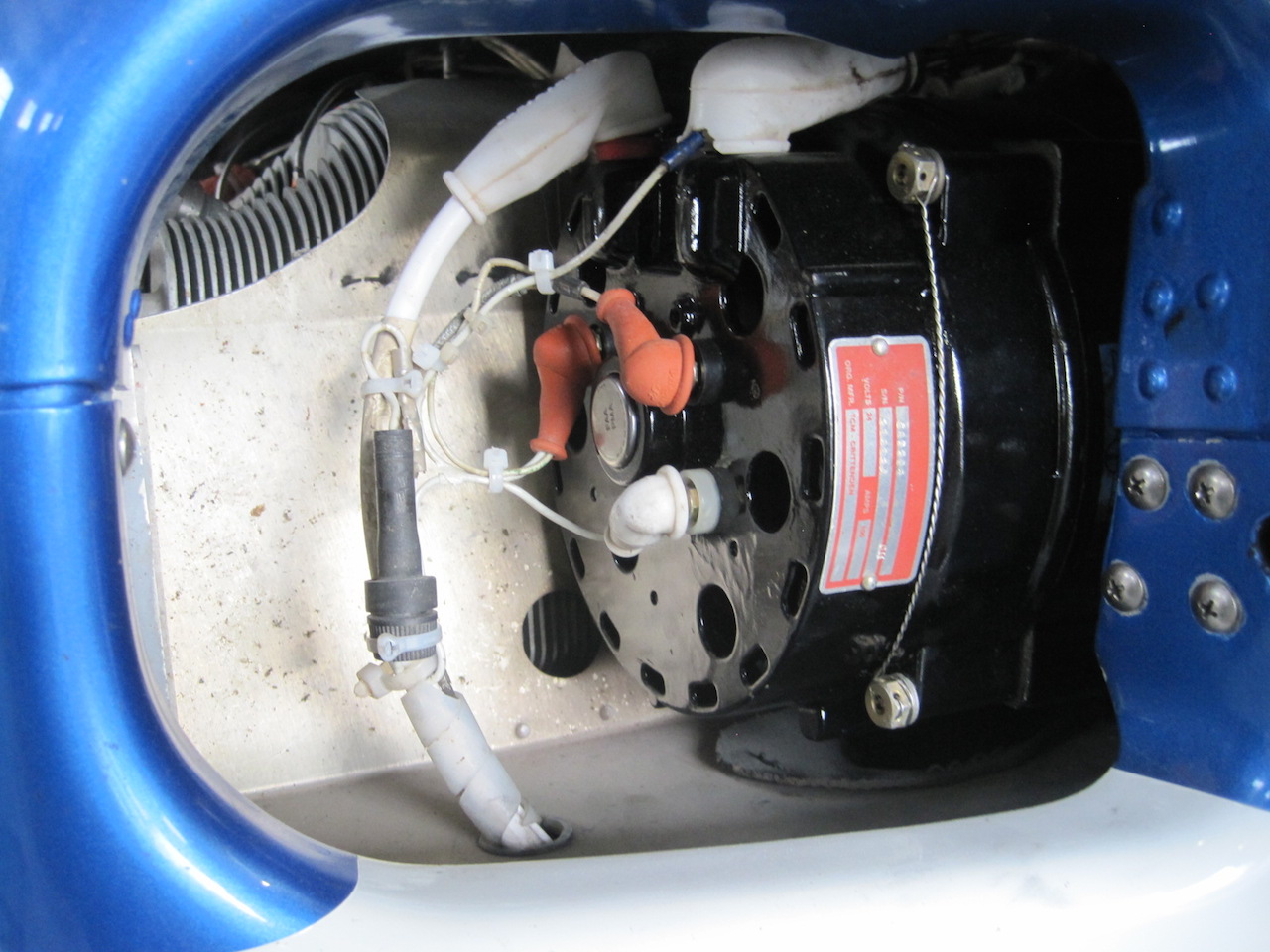

An accelerometer usually uses a concentrated mass (seismic mass), which resists movement because of its inertia. The displacement of the seismic mass relative to its supporting frame or container is used as a measure of acceleration.

Aircraft Accelerometer

Although the use of flight data gathered during day-to-day normal flight operations is becoming increasingly important for owners and operators of aircraft, the FDR's historically famous role remains being one of the so-called "black boxes" which are recovered following an accident

Hermetically Sealed For Safety

(the other black box being the cockpit voice recorder (CVR)). This is because in the past half-century in which the use of FDRs and CVRs have been mandated by aviation regulatory authorities around the world, the knowledge gained from these devices have led to major improvements in air safety, not only in the mechanical aspects of

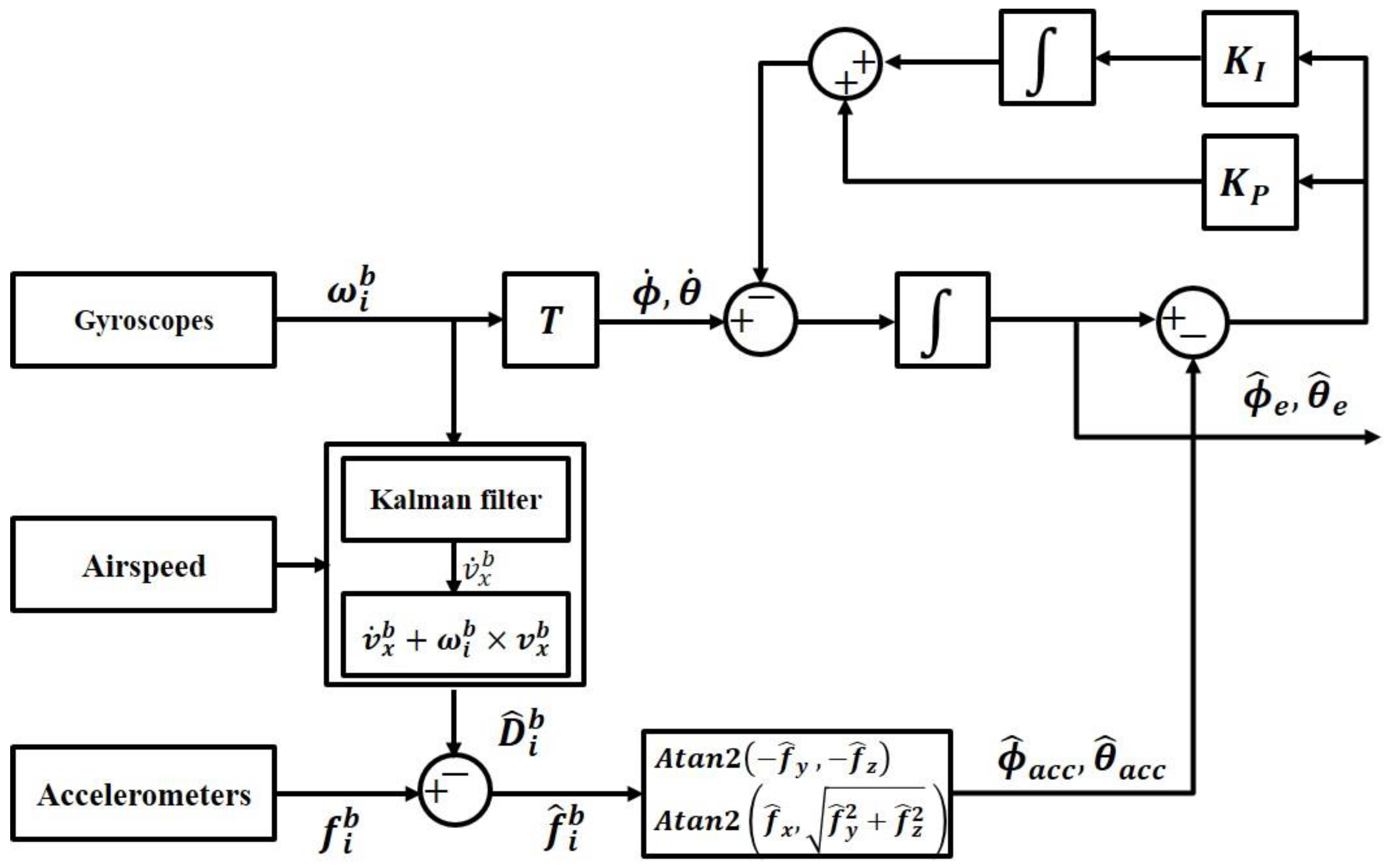

aircraft themselves, but in how flight crews conduct flight operations. It is used mainly on Navigation or Guidance Systems called Inertial Navigation System (INS), or Inertial Reference System (IRS), or Inertial Reference Unit (IRU) or Air Data Inertial Reference Unit (ADIRU).

These systems use Accelerometers Gyroscopes and electronic circuitry to provide accurate Guidance, Navigation, Position calculation, Speed measurement and Attitude determination, factors absolutely necessary for the auto pilot operation on sea and air vehicles. On airplanes the Flight Data Recorder uses accelerometers to measure and record acceleration forces on the three axis of the vehicle, and on cars the accelerometers are used to deploy the air bags at the right time.

Whether an aircraft is taxiing, taking off, landing or in an extended period of cruising flight, it is generating vast amounts of data. In modern aircraft, almost all of this digital data is already being generated for the aircraft systems, which require it.

How Do Accelerometers Work?

While recorded flight data continued to be important in understanding how new aircraft designs were performing purely from an engineering standpoint, with increasing numbers of people flying aboard commercial airliners by the 1950s – the challenge of understanding aviation accidents of production airplanes became the driving interest in understanding

what – and why – things sometimes went wrong during flight. Realizing that accident investigators very rarely had the luxury of first-hand observations of the cockpit crew involved in accidents, in 1953 an Australian aviation engineer, David Warren, built the first flight data recorder that also recorded the conversation of the cockpit crew.

Warren realized that the comments of the flight crew, recorded concurrently with certain physical data about the airplane itself, could prove invaluable in determining why an accident happened. "Black Box" is the name widely used for a flight data recorder or cockpit voice recorder.

They are, however, not black, but are painted a high-visibility orange to help safety investigators locate them following an accident. So how did something that is universally orange become called "black"? There is no definitive answer, but it is possible that aviation black boxes may have originally picked up the moniker because some of the earliest flight data recorders which were developed in the early 1940s employed photographic film as the recording medium;

Where Is It Used?

therefore, the inside of the box had to be completely dark as a narrow beam of light "wrote" data on a strip of film. In the half-century since data and voice recorders have been required, equipment on all scheduled airlines flights, the devices have evolved to measure not just the early 1960s parameters of airspeed, altitude, heading and attitude (whether the nose of the airplane is pointed

up or down, or the wings are level or banked), but thousands of other parameters which can help pinpoint why an accident happened. Beyond the post-accident investigative importance of this information, the recorded data from normal, day-to-day flights is proving increasingly useful to aircraft owners and operators who periodically download it for computer analysis which can reveal maintenance concerns in their earliest stages of development

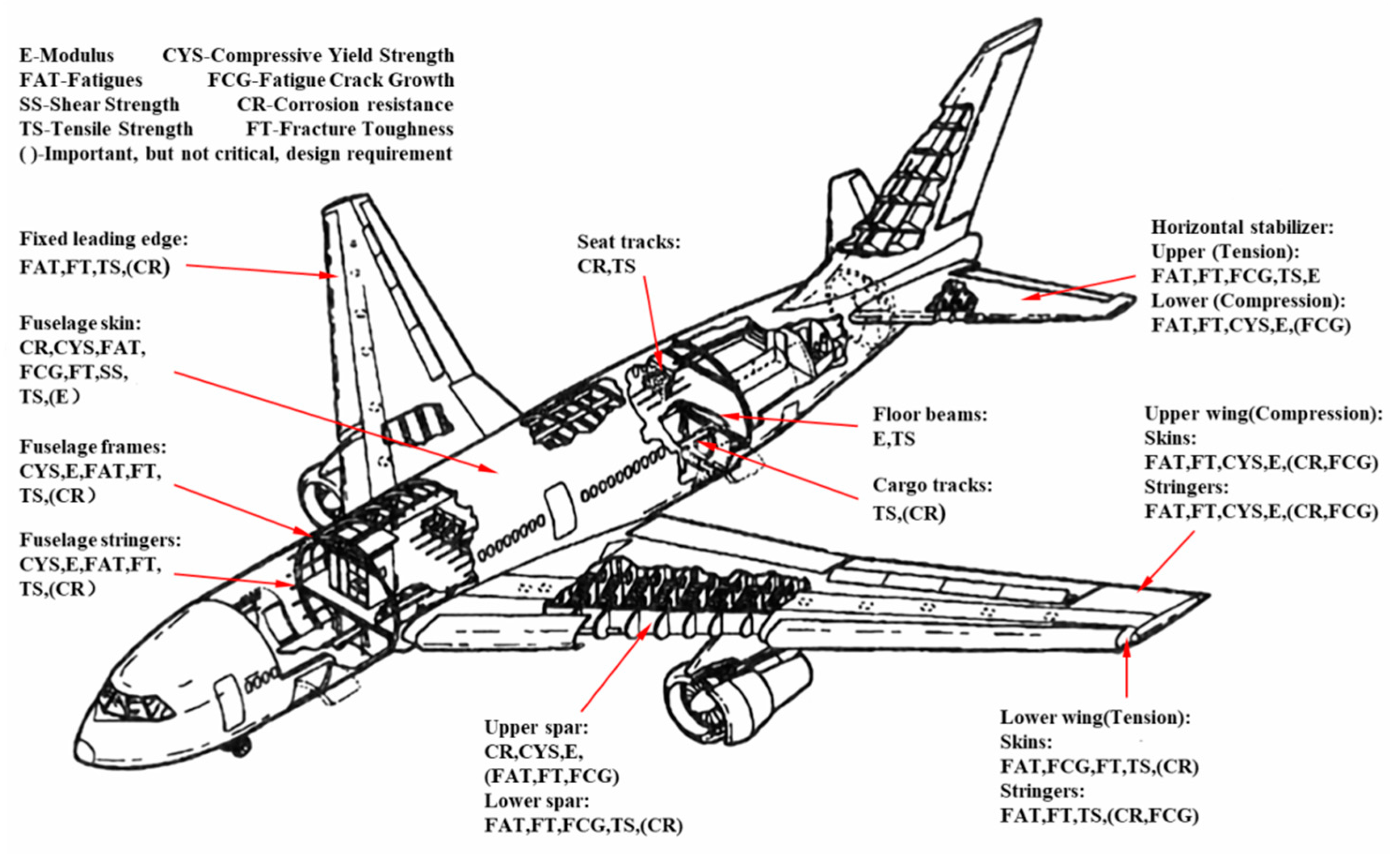

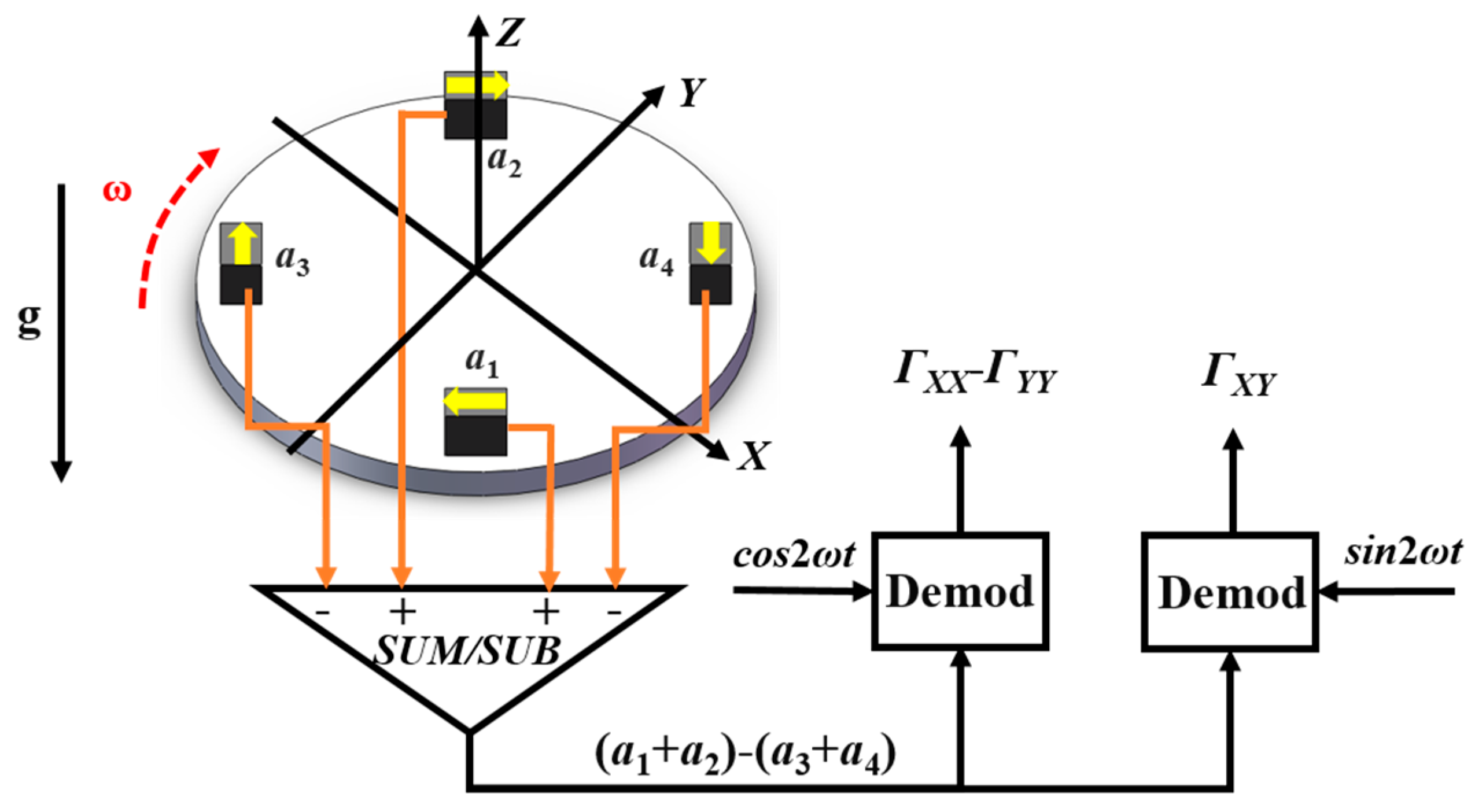

, or can help determine more cost-effective ways in which the aircraft can be operated. Looking at the schematic diagram above, we can see the proof mass in orange color placed between the magnets. Around the proof mass there is a torquer coil. The suspension metal blade of the proof mass in yellow color, comprise together with two plates above and below it, two capacitors of the same value when the proof mass is null.

An FDR always retains the last 25 hours of flight data by continuously recording over data which is more than 25 (operational) hours old. Because of this capacity, there is no non-stop or multi-stop flight which cannot be recorded in its entirety.

What Is An Accelerometer?

An FDR's memory can be configured to store more than 25 hours by employing data compression and other techniques. An accelerometer is an electromechanical device that will measure acceleration forces. These forces may be static, like the constant force of gravity pulling at your feet, or they could be dynamic - caused by changes in the speed and the direction of the movement (acceleration - deceleration, turns).

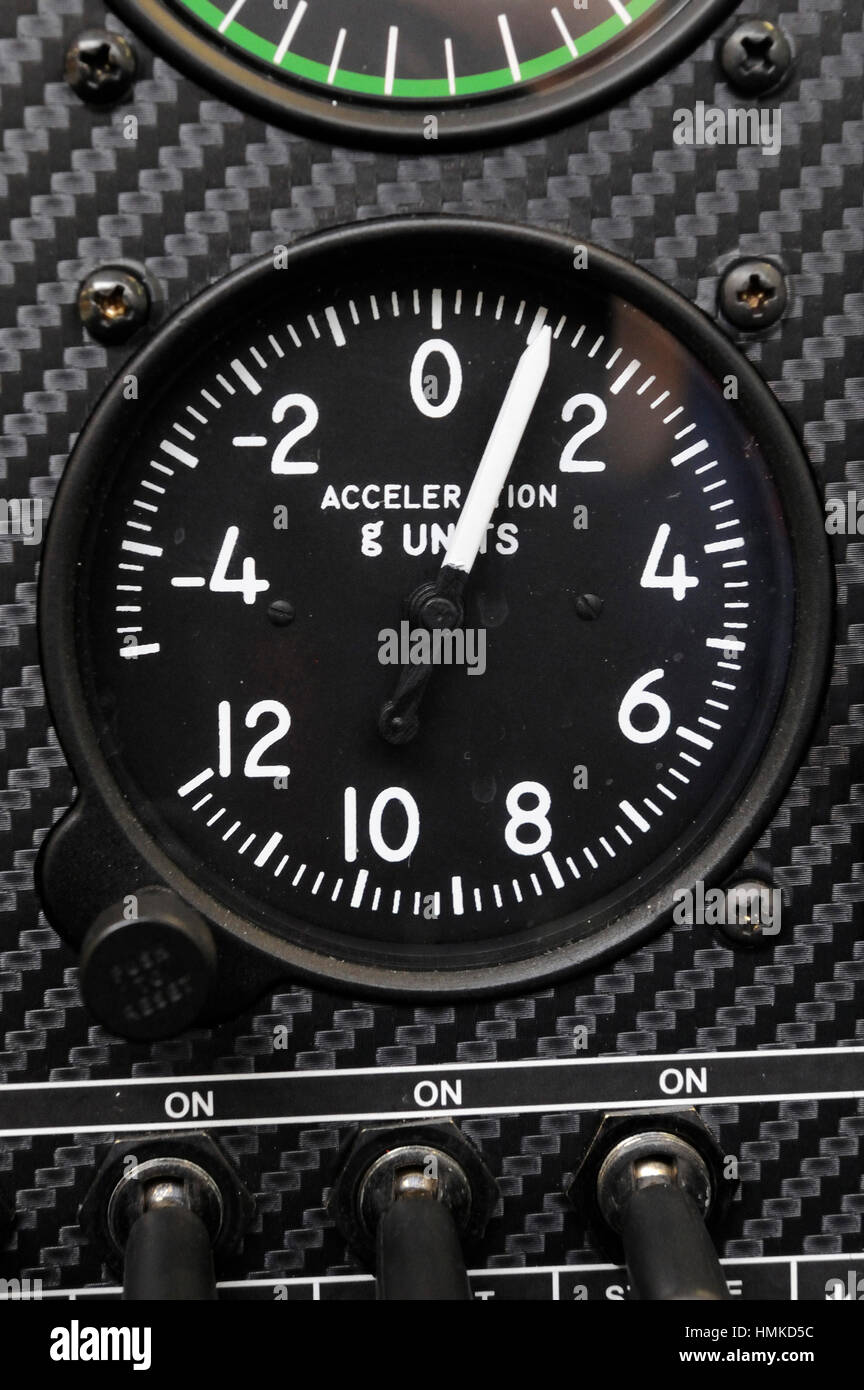

Models are available with or without integral lighting. A variety of ranges for every application make the QED instrument the logical choice for measuring vertical acceleration in aircraft. Because the QED cockpit accelerometer is fully mechanical with no electrical power required for operation, dead stick maneuvers can be measured, reset, and measured again.

More likely, though, the term "black box" became associated with aviation FDRs and CVRs because, broadly speaking, a black box is any electronic device which has an input and an output over which the operator of the device has no control, that is

, what goes on inside the device happens "in the dark" from the viewpoint of the operator. This is essentially the case with FDRs and CVRs – the devices automatically do their job with no involvement from the flight crew.

Designed For Long Operational Life

Accelerometers measure the levels of vibration in an engine or system. They detect faults and prevent potential damage. They enable you to achieve the reliability and accuracy you need for your engine, aircraft, helicopter, UAS, space or transportation application.

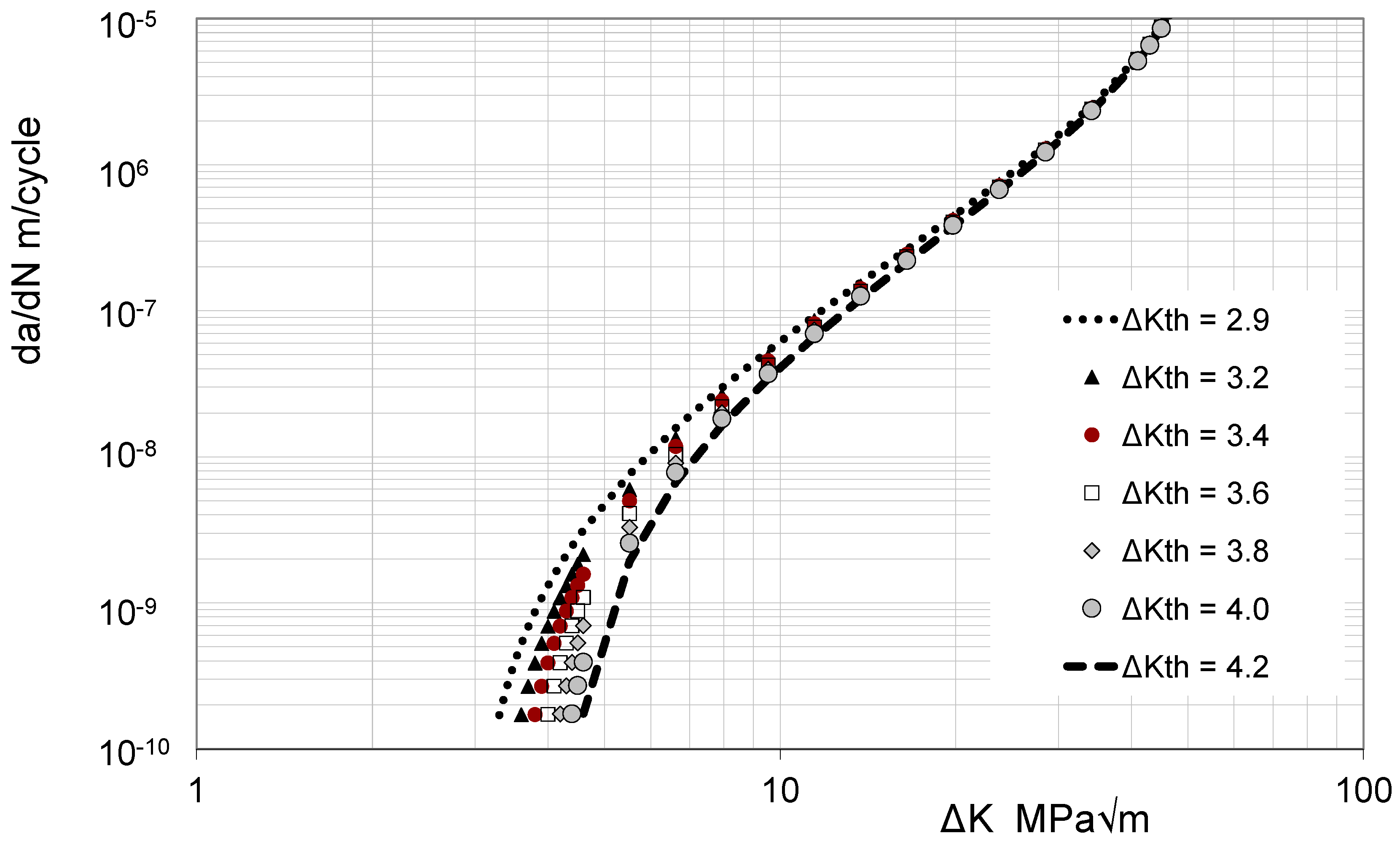

There are many different ways to make an accelerometer. Some accelerometers use the piezoelectric effect – they contain microscopic crystal structures that get stressed by accelerative forces, which cause a voltage to be generated. Another way to do it is by sensing changes in capacitance.

If you have two microstructures next to each other, they have a certain capacitance between them. If an accelerative force moves one of the structures, then the capacitance will change. Add some circuitry to convert from capacitance to voltage, and you will get an accelerometer.

There are even more methods, including the use of the piezoresistive effect, hot air bubbles, and light. For example, temperature and altitude (atmospheric pressure) data is needed by the engine control system, while airspeed, heading and position data is needed by the navigation system.

In these cases all the Flight Data Acquisition Unit (FDAU) needs to do is tap into the digital data stream of the respective systems. Other types of data are only critical in the investigation of an accident, and for this purpose dedicated sensors are installed which provide this information to the FDAU.

An example of this kind of data would be the output of an accelerometer, which measures the acceleration (G-forces) the aircraft is experiencing at any given moment. Acceleration along the input axis moves the proof mass.

Capacitive pickoff converts the position change into an electrical error signal to the servo amplifier. The servo amplifier nulls out the error signal by returning the proof mass to the zero-position using the torquer coil. The current in the torquer coil needed to null the error signal is the analog output signal representing acceleration.

The analog output signal is integrated once to give velocity and integrated a second time to give distance. These applications appreciate the quality and steady function of these instruments. Since the 1950s QED has been the manufacturer-of-choice for the Cockpit Accelerometer;

the G-force instrument preferred by the pilots of trainers and transport aircraft worldwide. In the original, mechanical version, the QED cockpit accelerometer continues to keep QED as the first choice for pilots of trainer and transport aircraft and for military forces in 28 countries.

Similar to the flash memory found in a myriad of consumer electronics, the digital data that has been collected by the FDAU is stored on memory chips. These chips are specifically made for FDRs, and are therefore more resistant to heat and G-forces than those found in consumer goods.

The Multi-Axial Accelerometer is an essential component in L3Harris' advanced accident-survivable flight recording systems designed for use in commercial and military aircraft. The hermetically sealed instrument houses single-, dual- or tri-axial sensors for measuring vertical, longitudinal and lateral acceleration.

To gain access to the latest technical publications, service bulletins and other pertinent information about your recorders or other L3Harris devices, operators and authorized repair facilities need to register with our technical support organization for the online library.

Our 60+ years of sensor and system expertise means our solutions are trusted by original equipment manufacturers (OEMs) around the world. We work hand in hand with our customers to tailor cost-effective solutions to each application.

From the time that Wilbur and Orville Wright made their first powered flight in 1903, there has been a need to record flight data. In the case of the Wrights, they wanted to know how many turns the propellers had made during a flight, which was information that was useful in determining – and improving – the propulsive efficiency with the propellers.

• Resistance to intense heat and "heat soaking": The CSMU must not only be able to withstand the intense heat of a raging fire, but the often more damaging effects of "heat soaking," which means a lower level of heat to which the

unit is subjected to for hours, such as residual fire that may burn for an extended period following an accident For the most part, the next 40 years of flight data was primarily of interest to those engaged in building and testing new aircraft designs and that information was recorded by hand during the test flights, or in post-flight pilot observations.

In 1939, however, two French inventors developed a device that automatically recorded several flight parameters on slowly moving photographic film that was exposed to a thin beam of light bent by moving mirrors. Because the container needed to be completely lightproof, some believe that this may have been the origin of the phrase "black box" as being synonymous with flight data recorder.

Flight Data Recorder (FDR) is a device which records multiple parameters of aircraft performance for the purpose of helping safety investigators determine the cause of an accident. Additionally, the recorded data can be used in normal (non-accident) operations to detect maintenance issues which may be developing, or to improve efficiency by better understanding how normal flight operations are being conducted.

It is fair to say that the one aspect of an FDR that distinguishes it from any other technological product ever made is its ability to survive an accident and still allow recovery of the stored data.

This is accomplished by the Crash-Survivable Memory Unit (CSMU), which is collectively the solid-state memory chips and a hardened metal container filled with specially designed heat insulating material. It is this container that provides the survivability, for it is able to withstand massive crushing loads, intense heat, and exceptionally high G-forces, all of which is proven by crash survivability testing.

The lightweight Multi-Axial Accelerometer is designed to give you peak performance, with an MTBF rating of over 50,000 hours. That's a long time by any measure and it means that you won't be worrying about the status of the accelerometer for at least the next 5.7 years (assuming you used it 24 hours a day during that period without ever turning the unit off).

Although among the general population the term is almost exclusively associated with the FDRs and CVRs carried aboard aircraft, in recent years "black box" is tied to a similar type of accident investigation technology being used on passenger ships and freighters.

In this maritime application the device is known as a hardened voyage recorder (HVR). And, it too is painted orange.

g meter for aircraft, accelerometer g meter, digital g meter, what is accelerometer, aircraft g meter for sale, what is accelerometer sensor, accelerometer for vibration measurement, what is accelerometer used for